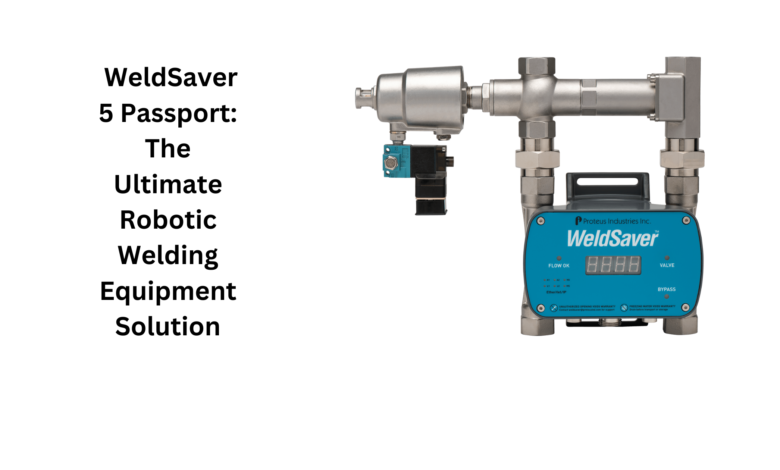

WeldSaver 5 Passport: The Ultimate Robotic Welding Equipment Solution

In the fast-evolving world of manufacturing, efficiency and accuracy are paramount. Robotic welding equipment has revolutionized the welding industry by introducing automation that enhances productivity and ensures consistent quality. Among the leading solutions is the WeldSaver 5 Passport, a state-of-the-art robotic welding equipment designed to meet the diverse needs of various industries. In this article, we’ll explore robotic welding equipment, the key features to look for, popular solutions in the market, and why the WeldSaver 5 Passport stands out.

What is Robotic Welding Equipment?

Robotic welding equipment refers to automated systems that utilize robotic arms to perform welding tasks. These methods can be programmed to conduct a welding process, including MIG, TIG, and spot welding. Robotic welding equipment is increasingly being adopted across industries because it can handle repetitive tasks with high precision and efficiency.

The main components of robotic welding equipment include:

- Controller: A computer system that programs and controls the robot’s movements and welding parameters.

- Welding Equipment: The tools and technologies necessary for performing different types of welding.

Key Features to Look for in Robotic Welding Equipment

When investing in robotic welding equipment, it’s essential to consider several vital features that can enhance productivity and efficiency:

- Versatility

Look for robotic welding equipment that can adapt to different welding processes and materials. The power to change between MIG, TIG, and other techniques allows for greater flexibility in manufacturing.

- Ease of Programming

User-friendly programming interfaces are crucial for operators to quickly set up and modify welding tasks. Advanced systems may offer intuitive graphical interfaces or teach pendant programming.

- Precision and Accuracy

High-quality robotic welding equipment should deliver consistent results with minimal deviation. Features like advanced sensors and real-time feedback systems ensure the welds meet specified standards.

- Integration Capability

Integrating robotic welding equipment with existing systems and workflows is essential for seamless operations. Compatibility with software and hardware can streamline the manufacturing process.

Conclusion

The rise of robotic welding equipment has transformed the manufacturing landscape, enabling companies to achieve higher levels of productivity and quality. Proteus Industries, Inc. is dedicated to providing advanced solutions for welding automation. With innovative products like our WeldSaver™ coolant flow sensors,The WeldSaver 5 Passport exemplifies the best in robotic welding technology, offering features that cater to a wide range of welding needs.

FAQs

- What is robotic welding equipment?

Robotic welding equipment refers to automated systems that use robotic arms to perform high-precision and efficient welding tasks.

- What are the advantages of utilizing robotic welding?

Robotic welding offers increased productivity, consistent quality, enhanced worker safety, and reduced labor costs.

- What types of welding can robotic equipment perform?

Robotic welding equipment can perform various types of welding, including MIG, TIG, and spot welding.

- How do I choose the right robotic welding equipment?

Consider factors like versatility, ease of programming, precision, maintenance support, and integration capabilities.

- What is the WeldSaver 5 Passport?

The WeldSaver 5 Passport is a leading robotic welding equipment solution known for its adaptive technology, compact design, and user-friendly interface.

- How does robotic welding equipment improve safety?

Robotic systems minimize human exposure to hazardous conditions by automating dangerous welding tasks, thereby enhancing workplace safety.

- Can robotic welding equipment be integrated with existing systems?

Many robotic welding solutions are designed to integrate seamlessly with existing manufacturing systems and workflows.

- What industries benefit from robotic welding equipment?

Industries such as automotive, aerospace, construction, and electronics frequently utilize robotic welding for its efficiency and precision.

- Is training required to operate robotic welding equipment?

While many systems are designed to be user-friendly, training is recommended to ensure operators can program and maintain the equipment effectively.