HD Industrial Endoscope Enhance Quality Control in Manufacturing

In the fast-paced world of manufacturing, ensuring quality control is paramount. Defects or issues in products can lead to significant financial losses and damage to a company’s reputation. One of the most effective tools for enhancing quality control is the HD industrial endoscope. This advanced technology allows manufacturers to inspect their processes and products with unparalleled precision. In this blog, we’ll explore how HD industrial endoscopes work, their benefits, and their impact on quality control in the manufacturing sector.

What is an HD Industrial Endoscope?

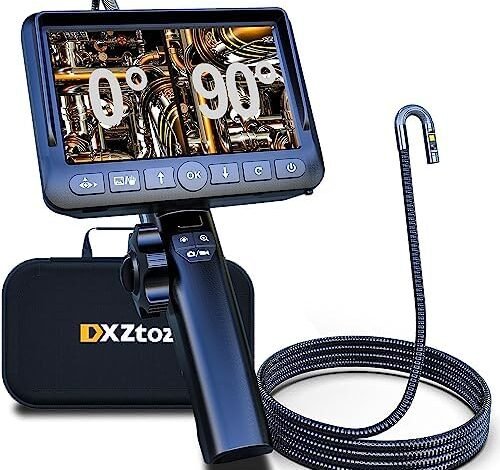

An HD industrial endoscope is a specialized inspection tool that features a high-definition camera attached to a long, flexible cable. This device allows operators to visually inspect hard-to-reach areas in machinery, assemblies, and other components without the need for disassembly. The camera transmits real-time images to a monitor, enabling technicians to detect issues quickly and accurately.

Key Features of HD Industrial Endoscopes

- High-Resolution Imaging: HD industrial endoscopes typically offer resolutions of 1080p or higher, ensuring clear and detailed images for effective inspection.

- Flexible and Rigid Options: These endoscopes come in various designs, including flexible cables for maneuvering through tight spaces and rigid borescopes for more straightforward inspections.

- LED Lighting: Built-in LED lights illuminate dark areas, making it easier to see potential problems in low-light environments.

- Water and Dust Resistance: Many HD industrial endoscopes are designed to withstand harsh conditions, making them suitable for various industrial environments.

- Recording Capability: Many models allow for video recording and image capture, providing a valuable archive for future reference and analysis.

The Role of HD Industrial Endoscopes in Quality Control

1. Early Detection of Defects

One of the most significant advantages of using HD industrial endoscopes is their ability to detect defects early in the manufacturing process. By inspecting components at various stages, manufacturers can identify issues such as cracks, corrosion, and misalignments before they lead to larger problems. Early detection helps to reduce rework and scrap rates, ultimately saving time and money.

2. In-Depth Inspections of Complex Components

Manufacturing processes often involve intricate assemblies that are challenging to inspect visually. HD industrial endoscopes provide the capability to conduct thorough inspections of these complex components. Whether it’s examining the interior of engines, checking welds, or inspecting pipelines, these endoscopes allow technicians to see areas that would otherwise be inaccessible, ensuring that every part meets the required specifications.

3. Improved Process Efficiency

Incorporating HD industrial endoscopes into quality control processes can lead to increased efficiency. With quick access to visual information, operators can make informed decisions faster. This real-time feedback reduces downtime and streamlines the inspection process, allowing for quicker production cycles without sacrificing quality.

4. Comprehensive Documentation

Quality control is not just about identifying problems; it also involves maintaining thorough documentation of inspections. HD industrial endoscopes often come with recording capabilities, allowing technicians to capture video and images during inspections. This documentation serves as a valuable resource for quality assurance, providing evidence of compliance with industry standards and facilitating audits.

Industries Benefiting from HD Industrial Endoscopes

HD industrial endoscopes are versatile tools used across various industries, including:

- Automotive: Inspecting engines, exhaust systems, and other critical components.

- Aerospace: Ensuring the integrity of aircraft parts and assemblies.

- Manufacturing: Checking machinery and assembly lines for defects.

- Construction: Inspecting structural components and foundations.

Conclusion

HD industrial endoscopes are revolutionizing quality control in the manufacturing sector. By providing clear, high-resolution images of hard-to-reach areas, these tools enable early defect detection, improve process efficiency, and enhance overall product quality. As industries continue to evolve, integrating advanced inspection technologies like HD industrial endoscopes will be crucial in maintaining high standards and ensuring customer satisfaction.